Company Profile

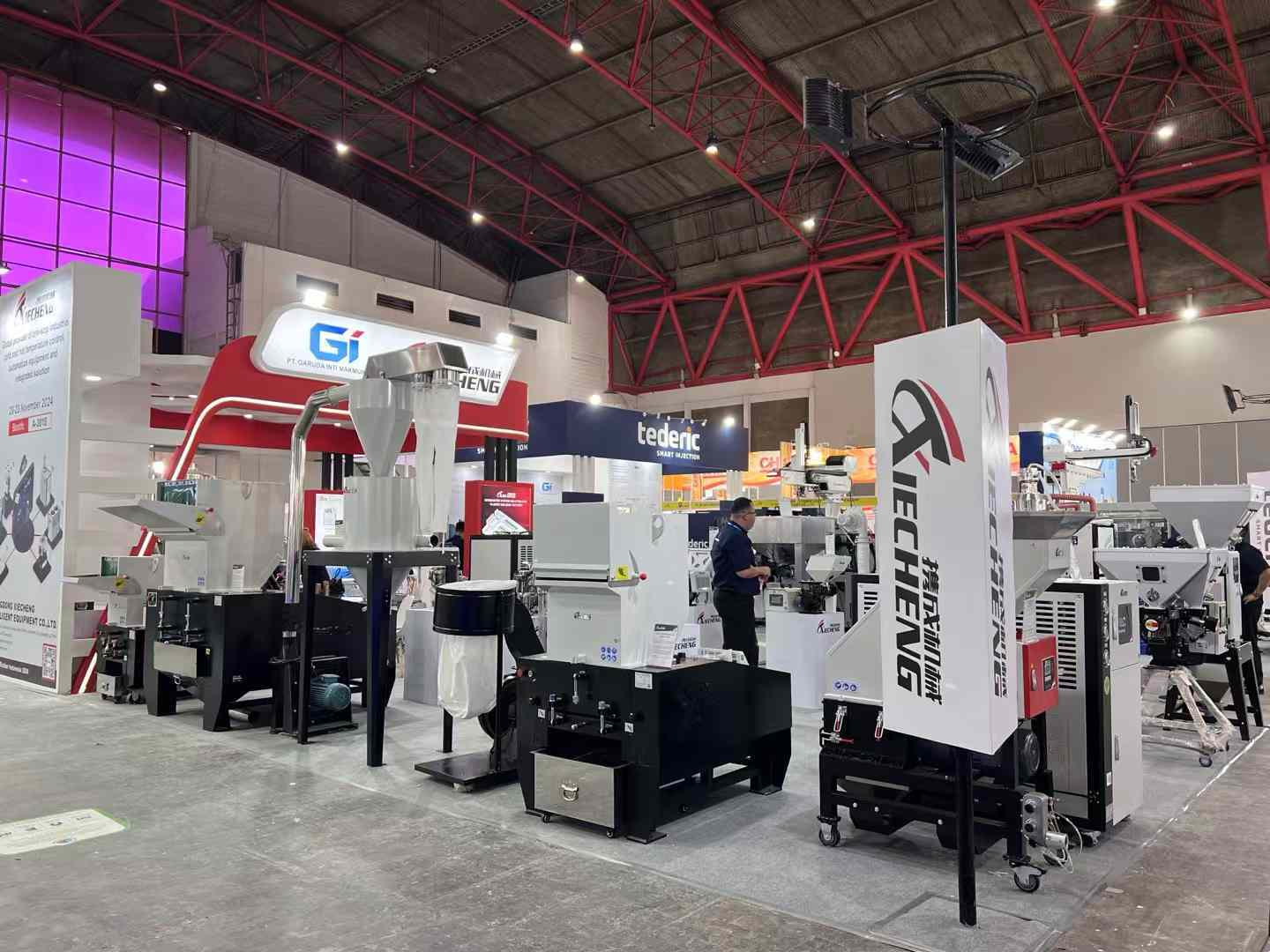

PT. Garuda Inti Makmur Abadi, an authorized plastic injection molding machine manufacturer and distributor for TEDERIC Injection Molding Machine, and exclusive agency specialized in plastic machinery and auxiliary equipment.

Our company provide not only machinery production and distribution, but also as one stop solution for our valued customers. Our services include consulting, advisory, design, cost control, procurement, after sales, and technical support.

In this era of competition, manufacturing industry are forced to be efficient in production process, and it is our expertise to provide best solution to any needs. With decades of experience, we can assure you that every challenge to us, will result in great opportunities.

*****

PT. Garuda Inti Makmur Abadi, adalah manufaktur dan distributor resmi TEDERIC Injection Molding Machine, dan agen eksklusif di bidang mesin dan perlengkapan pendukung untuk industri plastik.

Perusahaan kami selain mendistribusikan mesin, juga sebagai layanan satu pintu untuk pelanggan kami. Layanan kami meliputi konsultasi, desain, pengadaan, purna jual, dan layanan teknis.

Di era kompetisi saat ini, industri manufaktur dituntut untuk efisien dalam proses produksi. Oleh karena itu, tim ahli kami dibutuhkan untuk memberikan solusi terbaik atas segala kebutuhan anda. Dengan pengalaman yang ada, kami yakin setiap tantangan akan menghasilkan kesempatan yang luar biasa.

Our company provide not only machinery production and distribution, but also as one stop solution for our valued customers. Our services include consulting, advisory, design, cost control, procurement, after sales, and technical support.

In this era of competition, manufacturing industry are forced to be efficient in production process, and it is our expertise to provide best solution to any needs. With decades of experience, we can assure you that every challenge to us, will result in great opportunities.

*****

PT. Garuda Inti Makmur Abadi, adalah manufaktur dan distributor resmi TEDERIC Injection Molding Machine, dan agen eksklusif di bidang mesin dan perlengkapan pendukung untuk industri plastik.

Perusahaan kami selain mendistribusikan mesin, juga sebagai layanan satu pintu untuk pelanggan kami. Layanan kami meliputi konsultasi, desain, pengadaan, purna jual, dan layanan teknis.

Di era kompetisi saat ini, industri manufaktur dituntut untuk efisien dalam proses produksi. Oleh karena itu, tim ahli kami dibutuhkan untuk memberikan solusi terbaik atas segala kebutuhan anda. Dengan pengalaman yang ada, kami yakin setiap tantangan akan menghasilkan kesempatan yang luar biasa.

About us

Customers

TEDERIC Injection Molding Machine

TEDERIC Injection Molding Machine, is widely used for manufacturing plastic products by the injection molding process. It consists of two main parts, an injection unit and a clamping unit.

Features:

1.The electronic ruler is installed on the cross-head, to achieve a more precise positioning.

2.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly.

3.Connected movable plate, improves its rigidity and reduces deformation.

4.Connected thrust bearing, improves its strength and stills itself with lock shaft to ensures zero abrasion.

5.Precise toggle design, for speeds and stabilizes mold opening and closing.

Features:

1.The electronic ruler is installed on the cross-head, to achieve a more precise positioning.

2.The front connecting rod uses connected structure, increases the rod strength, and easy for assembly.

3.Connected movable plate, improves its rigidity and reduces deformation.

4.Connected thrust bearing, improves its strength and stills itself with lock shaft to ensures zero abrasion.

5.Precise toggle design, for speeds and stabilizes mold opening and closing.

Extrusion Blow Machine

Extrusion blow machine is specified to manufacturing process by which hollow plastic parts are formed and joined together. It is also used for forming bottles or other hollow shapes.

Features:

1. PLC with touch screen and human machine interface operation.

2. Equipped with alloy screw for high efficiency and low power consumption.

3. Dies Head made with high quality nitriding alloy steel.

4.Hydraulic with servo motor driven.

5.Optional Parison Control

Features:

1. PLC with touch screen and human machine interface operation.

2. Equipped with alloy screw for high efficiency and low power consumption.

3. Dies Head made with high quality nitriding alloy steel.

4.Hydraulic with servo motor driven.

5.Optional Parison Control

STRETCH BLOW MACHINE

Full Automatic Stretch Blow Molding Machine, Features :

1. Full Servo system with Chain Driving Servo, Stretching Servo and Clamping Servo

2. Equipped With Auto Unscramble - Auto Loading system

3. High-pressure blowing valve made of aluminum alloy, equipped with AIR-RECOVEY device.

4. Fully Automatic machine, easy operation with HMI

5. All PID Controlled system

Semi Automatic Stretch Blow Molding Machine, Features :

1. PLC and Computer controlled , for stable and easy operation

2. German Festo and Japan SMC pneumatic parts

3. Energy Saving and Compact Mechanical Design

1. Full Servo system with Chain Driving Servo, Stretching Servo and Clamping Servo

2. Equipped With Auto Unscramble - Auto Loading system

3. High-pressure blowing valve made of aluminum alloy, equipped with AIR-RECOVEY device.

4. Fully Automatic machine, easy operation with HMI

5. All PID Controlled system

Semi Automatic Stretch Blow Molding Machine, Features :

1. PLC and Computer controlled , for stable and easy operation

2. German Festo and Japan SMC pneumatic parts

3. Energy Saving and Compact Mechanical Design

Injection and Blow Molds

There are many different types of molds ranging from the simple prototype, inject-mold, thin-wall, PET-preform, insert-molds, blow-molds, to the extremely complex multi-cavity mold. Our partnership with local and multinational mold-maker, has given us the advantage of affordable molds without compromising the quality. We adapt latest mold technology such as hot-runner system, IML in mold labeling, auto de-flashing, high-speed mold, stack-mold, etc.

When customers are not sure exactly what kind of mold will meet their needs, we can analyze the information and determine the right type of mold to fit the need.

When customers are not sure exactly what kind of mold will meet their needs, we can analyze the information and determine the right type of mold to fit the need.

Extruder and Pelletizer

Extrusion Machine and Pelletizer

With Single Stage or Double Stage Extrusion System

Features :

1. Feeder Belt Conveyor for Rigid Materials

2. Film Force Feeding Technology for Flexible materials.

3. Single Stage for energy saving, or Double Stage for extra purity.

4. High speed cutting pelletizer

5. Various materials compatible, PP / PE / ABS / PC / PA / PET / Etc.

With Single Stage or Double Stage Extrusion System

Features :

1. Feeder Belt Conveyor for Rigid Materials

2. Film Force Feeding Technology for Flexible materials.

3. Single Stage for energy saving, or Double Stage for extra purity.

4. High speed cutting pelletizer

5. Various materials compatible, PP / PE / ABS / PC / PA / PET / Etc.

High Speed Crusher

Specially designed for crushing various rigid plastic to recycle with high - efficiency.

Superior cutter design to ensure even force to each blade, giving strong shearing force to reduce cutter wearable.

Equipped with multiple safety device to ensure protection.

Features:

1. All steel welded frame, very durable

2. Simplified design, easy cleaning, and maintenance

3. SKD-11 steel cutter, sharp blade, easy to replace and durable

4. Crush all kinds of soft and hard plastic, fast and easy

5. Equipped with motor overrun and electric chain protection system to ensure user safety

6. Choices of different blades and screen mesh

7. Optional bearing, rotor and chamber cooling

8. Optional cyclone blower and dust separation

Specification: High Speed Crusher

Sound-proof Crusher

Superior cutter design to ensure even force to each blade, giving strong shearing force to reduce cutter wearable.

Equipped with multiple safety device to ensure protection.

Features:

1. All steel welded frame, very durable

2. Simplified design, easy cleaning, and maintenance

3. SKD-11 steel cutter, sharp blade, easy to replace and durable

4. Crush all kinds of soft and hard plastic, fast and easy

5. Equipped with motor overrun and electric chain protection system to ensure user safety

6. Choices of different blades and screen mesh

7. Optional bearing, rotor and chamber cooling

8. Optional cyclone blower and dust separation

Specification: High Speed Crusher

Sound-proof Crusher

Low Speed Crusher

Low and medium speed crusher with 25 - 150 rpm, which specially designed for low noise and low dust recycling.

Suitable for inline crushing system. Compatible with proportional valve and autoloader for automatic mixing system.

Features:

1. All steel welded frame, very durable

2. Simplified design, easy cleaning, and maintenance

3. SKD-11 steel cutter, sharp blade, easy to replace and durable

4. Crush all kinds of soft and hard plastic, fast and easy

5. Equipped with motor overrun and electric chain protection system to ensure user safety

6. Choices of different blades and screen mesh

7. Optional bearing, rotor and chamber cooling

8. Optional cyclone blower and dust separation

Specification: Low Speed Crusher

Medium Speed Crusher

Suitable for inline crushing system. Compatible with proportional valve and autoloader for automatic mixing system.

Features:

1. All steel welded frame, very durable

2. Simplified design, easy cleaning, and maintenance

3. SKD-11 steel cutter, sharp blade, easy to replace and durable

4. Crush all kinds of soft and hard plastic, fast and easy

5. Equipped with motor overrun and electric chain protection system to ensure user safety

6. Choices of different blades and screen mesh

7. Optional bearing, rotor and chamber cooling

8. Optional cyclone blower and dust separation

Specification: Low Speed Crusher

Medium Speed Crusher

Lumps Recycle

Single and Double shaft lumps recycle, is used to shred plastic startup lumps, big block material, thick wall pipe and other plastic material which is difficult to process by standard crusher machine. Made with superior shaft structure design, low noise, durable, and easy blades changeable.

Features:

1. big feeding inlet to ensure easy loading for big size material.

2. The rotary and cutting blade with special design,for high efficiency and capacity.

3. Machine is controlled by PLC system, with auto reverse and auto shutdown system for emergency protection.

4. Equipped with Heavy duty low speed - high torsion gear box. result in low noise and low dust output.

5. SKD-11 blade material to ensure a long lifetime.

Advantages:

1. Low noise, low energy consumption

2. Unique power design, detachable, and convenient for cleaning, maintenance, and service

3. PLC program control, safe and reliable utilization, over-load protection, auto reverse and auto shutdown.

4. Strong shredding capacity and frame

Specification: Lumps Recycle

Features:

1. big feeding inlet to ensure easy loading for big size material.

2. The rotary and cutting blade with special design,for high efficiency and capacity.

3. Machine is controlled by PLC system, with auto reverse and auto shutdown system for emergency protection.

4. Equipped with Heavy duty low speed - high torsion gear box. result in low noise and low dust output.

5. SKD-11 blade material to ensure a long lifetime.

Advantages:

1. Low noise, low energy consumption

2. Unique power design, detachable, and convenient for cleaning, maintenance, and service

3. PLC program control, safe and reliable utilization, over-load protection, auto reverse and auto shutdown.

4. Strong shredding capacity and frame

Specification: Lumps Recycle

Vibrating Dust Separator

Vibrating Dust Separator convey material forward at a straight line, in high accuracy, stability and large output. Operates with low power consumption, low noise, and long life cycle. Easy maintenance, and fully enclosed structure. It contains double layer screening with high quality stainless steel screen.

Features:

1. Tilt design structure for best and optimal effect in screening process.

2. Easy cleaning and easy changeable screen size

3. Full Stainless steel body

4. Light weight and easily movable

Specification: Vibrating Dust Separator

Features:

1. Tilt design structure for best and optimal effect in screening process.

2. Easy cleaning and easy changeable screen size

3. Full Stainless steel body

4. Light weight and easily movable

Specification: Vibrating Dust Separator

Metal Separator

Avoid the risk of metal contaminants in the final product. With our metal separator, regardless what the contaminant is made of, iron, steel, stainless steel or non-ferrous metals, such as aluminium, copper and brass, our metal detection systems will identify all.

Features:

1. Detect magnetic and non-magnetic metal contaminants with extreme precision

2. Prevent damage to machinery and production downtime

3. Ensure product quality in line with the required standards and certifications

4. Protection against customer complaints and recalls

5. Low energy consumption

Specification: Metal Separator

Features:

1. Detect magnetic and non-magnetic metal contaminants with extreme precision

2. Prevent damage to machinery and production downtime

3. Ensure product quality in line with the required standards and certifications

4. Protection against customer complaints and recalls

5. Low energy consumption

Specification: Metal Separator

Color Mixer

Color mixer are equipped with vertical paddle to mix material fast and homogeneous.

Vertical and horizontal structure design to adapt with different material mixing.

Features:

1. It is equipped with pinwheel gear motor, which is low noise and durable.

2. Complete uniform mixing in a short time, low energy consumption and high efficiency;

3. The barrel lid and the bottom of the barrel are stamped and formed, which is highly durable;

4. Adjustable timer, 0-30 minute for effectiveness and efficiency

Specification: Vertical Color Mixer

Screw Color Mixer

Vertical and horizontal structure design to adapt with different material mixing.

Features:

1. It is equipped with pinwheel gear motor, which is low noise and durable.

2. Complete uniform mixing in a short time, low energy consumption and high efficiency;

3. The barrel lid and the bottom of the barrel are stamped and formed, which is highly durable;

4. Adjustable timer, 0-30 minute for effectiveness and efficiency

Specification: Vertical Color Mixer

Screw Color Mixer

Dosser

Volumetric dosser and Gravimetric blender are adaptable to auto-proportion mixing of virgin materials, regrinds, master-batch or additives, adaptable to injection, extrusion, or blow molding field.

Microprocessor accurately controls the dosing process with high precision with a deviation of ± 1%. This dosser can connect with various molding machine signals in synchronicity, to ensure the stability of the products

Features:

1. Screw made of 304 stainless steel and chrome plated.

2. PLC controller to quickly and accurately measure the color master-batch and adding proportion

3. Adopt high precision hybrid stepping motor, accurate dosing, and wide output range

4. Transparent visual window

5. Optional mixing base with a transparent window, for easy observation of the mixing output.

6. Designed with modular and detachable structure, which can be quickly removed and replaced with an internal screw and sleeve.

Specification: Volumetric Screw Doser

Gravimetric Blender

Microprocessor accurately controls the dosing process with high precision with a deviation of ± 1%. This dosser can connect with various molding machine signals in synchronicity, to ensure the stability of the products

Features:

1. Screw made of 304 stainless steel and chrome plated.

2. PLC controller to quickly and accurately measure the color master-batch and adding proportion

3. Adopt high precision hybrid stepping motor, accurate dosing, and wide output range

4. Transparent visual window

5. Optional mixing base with a transparent window, for easy observation of the mixing output.

6. Designed with modular and detachable structure, which can be quickly removed and replaced with an internal screw and sleeve.

Specification: Volumetric Screw Doser

Gravimetric Blender

Single Autoloader

Single Autoloader uses carbon brush high-speed motor. The design is small, ergonomic, light weight, save space, easy installation and operation. It can be mounted onto hopper dryer or directly to injection molding machine.

Features:

1. Stainless Steel construction

2. Mechanical flap for mounting onto hopper dryer

3. Photo-Sensor for direct mounting to injection molding machine

4. Auto cleaning function

5. Automatic material shortage alarm

Specification: Autoloader

Features:

1. Stainless Steel construction

2. Mechanical flap for mounting onto hopper dryer

3. Photo-Sensor for direct mounting to injection molding machine

4. Auto cleaning function

5. Automatic material shortage alarm

Specification: Autoloader

Detach Autoloader

Autoloader is widely used in the raw material conveying industry of injection molding machines, extrusion, and blow molding.

All open design structure, easy maintenance for the blower station

The microcomputer control system accurately control the operation with indicator light to clearly understand the operation state of the machine.

Features:

1 Stainless steel hopper receiver, clean and convenient

2. Microcomputer to control features and easy operation with multiple alarm indicator.

3. Motor overload protection for safety operation.

4. Built-in dust collecting bin for open-type loader

5. Optional proportional valve to automatically mix virgin and recycle material.

Specification: Autoloader

All open design structure, easy maintenance for the blower station

The microcomputer control system accurately control the operation with indicator light to clearly understand the operation state of the machine.

Features:

1 Stainless steel hopper receiver, clean and convenient

2. Microcomputer to control features and easy operation with multiple alarm indicator.

3. Motor overload protection for safety operation.

4. Built-in dust collecting bin for open-type loader

5. Optional proportional valve to automatically mix virgin and recycle material.

Specification: Autoloader

Central Feeding System

Central Feeding System is an overall solution to achieve an unattended, autonomous and continuous operation. The design is tailored suit to customer's need, including the unique layout of material room, machinery, and auxiliary of the whole plant.

An intelligent micro computer system is adopted to control the overall machine stations for 24/7. It can easily be upgraded with industry 4.0 interface to match the current technology.

Features:

1. Intelligent micro computer system with PLC and HMI interface

2. Conveying unit with shut-off suction box to ensure a clean and stable material distribution

3. Dynamic unit with electronic pressure relieve valve

4. Modular design , flexible to expand and easy maintenance.

An intelligent micro computer system is adopted to control the overall machine stations for 24/7. It can easily be upgraded with industry 4.0 interface to match the current technology.

Features:

1. Intelligent micro computer system with PLC and HMI interface

2. Conveying unit with shut-off suction box to ensure a clean and stable material distribution

3. Dynamic unit with electronic pressure relieve valve

4. Modular design , flexible to expand and easy maintenance.

Hopper Dryer

Hopper Dryer are the most efficient and economical means of drying plastic materials.

The hopper is made of stainless steel and has the functions of “hot air blowing” and “whirlwind exhaust” and double-layer insulated barrels. It is especially suitable for use with dehumidifiers to dry plastic materials.

Features:

1. With P.I.D system for precise temperature control

2. Unique down-blowing duct design, which can evenly disperse hot air, keep plastic dry, stabilize temperature and improve drying efficiency

3. Stainless steel double-layer insulation barrel with window

4. The thermal overload protection device, safe and reliable

Specification: Hopper Dryer

The hopper is made of stainless steel and has the functions of “hot air blowing” and “whirlwind exhaust” and double-layer insulated barrels. It is especially suitable for use with dehumidifiers to dry plastic materials.

Features:

1. With P.I.D system for precise temperature control

2. Unique down-blowing duct design, which can evenly disperse hot air, keep plastic dry, stabilize temperature and improve drying efficiency

3. Stainless steel double-layer insulation barrel with window

4. The thermal overload protection device, safe and reliable

Specification: Hopper Dryer

Dehumidifier

All-in-one dehumidifying dryer gathers dehumidifying, drying, and two-stage conveying into one single unit. Very suitable for drying hygroscopic material such as PA, PC, PBT, PET, ABS. It has a dew-point of below -45℃ ~-50℃. It is combined with honeycomb rotor and down blowing fully stainless steel euro hopper dryer, adopted P.I.D temperature control. LCD touch screen and optional dew point monitor.

Features:

1. Stable dew-point of less than -45℃.

2. The closed-loop conveying device eliminates the possibility of moisture regains during material conveying.

3. Double layer hopper structure enhances thermal insulation and achieves a higher energy saving rate. It maintains a steady temperature and increases drying efficiency.

4. The conveying system is equipped with material cut-off valve to make sure no remains material in the tube.

5. Micro-computer control panel, easy to operate and clear fault code display.

Specification: 3 in 1 Compact Dehumidifier

Features:

1. Stable dew-point of less than -45℃.

2. The closed-loop conveying device eliminates the possibility of moisture regains during material conveying.

3. Double layer hopper structure enhances thermal insulation and achieves a higher energy saving rate. It maintains a steady temperature and increases drying efficiency.

4. The conveying system is equipped with material cut-off valve to make sure no remains material in the tube.

5. Micro-computer control panel, easy to operate and clear fault code display.

Specification: 3 in 1 Compact Dehumidifier

Air Cooled Chiller

The chiller is widely used to reduce the temperature of injection molds and improve the quality of plastic products.

The cooling water temperature can be set automatically.

The Air-cooled Chiller is to provide a cooling process for better industrial production. In the plastic molding industry, it improves the quality of products and shortens the period of injection molding cycles. Hence maximizes the productivity of plastic molding manufacturing.

Features

1. Built-in stainless steel water tank, high performance, high flow special pump.

2. Japan Panasonic compressor, high efficiency, low noise, quiet operation

3. Emerson imported refrigeration parts

4. SIEMENS Electrical parts

5. All insulated pipe to prevent local convection of the pipeline

Specification: Air Cooled Chiller

Air Cooled - Screw Chiller

The cooling water temperature can be set automatically.

The Air-cooled Chiller is to provide a cooling process for better industrial production. In the plastic molding industry, it improves the quality of products and shortens the period of injection molding cycles. Hence maximizes the productivity of plastic molding manufacturing.

Features

1. Built-in stainless steel water tank, high performance, high flow special pump.

2. Japan Panasonic compressor, high efficiency, low noise, quiet operation

3. Emerson imported refrigeration parts

4. SIEMENS Electrical parts

5. All insulated pipe to prevent local convection of the pipeline

Specification: Air Cooled Chiller

Air Cooled - Screw Chiller

Water Cooled Chiller

The chiller is widely used to reduce the temperature of injection molds and improve the quality of plastic products.

The cooling water temperature can be set automatically.

The Water-cooled Chiller is to provide a cooling process for better industrial production. In the plastic molding industry, it improves the quality of products and shortens the period of injection molding cycles. Hence maximizes the productivity of plastic molding manufacturing.

Features

1. Built-in stainless steel water tank, high performance, high flow special pump.

2. Japan Panasonic compressor, high efficiency, low noise, quiet operation

3. Emerson imported refrigeration parts

4. SIEMENS Electrical parts

5. All insulated pipe to prevent local convection of the pipeline

Specification: Water Cooled Chiller

Water Cooled - Screw Chiller

The cooling water temperature can be set automatically.

The Water-cooled Chiller is to provide a cooling process for better industrial production. In the plastic molding industry, it improves the quality of products and shortens the period of injection molding cycles. Hence maximizes the productivity of plastic molding manufacturing.

Features

1. Built-in stainless steel water tank, high performance, high flow special pump.

2. Japan Panasonic compressor, high efficiency, low noise, quiet operation

3. Emerson imported refrigeration parts

4. SIEMENS Electrical parts

5. All insulated pipe to prevent local convection of the pipeline

Specification: Water Cooled Chiller

Water Cooled - Screw Chiller

Mold Temp Controller

MTC - Mold Temperature Controller, uses water or oil as heating agent to perform heat exchanging by direct or indirect system.

Operation temperature for water type MTC is 30-100°C whereas oil type MTC can reach 45-160°C.

Features:

1. PID temperature control – regulates error within 0.1°C, continuously and constantly, with high efficiency and energy saving.

2. Automatic exhaust & shut down cooling protection, thermostatic and circuit alarm, phase fault protection, pump protection, overheat protection, oil shortage protection.

3. LCD shows the actual and set temperatures – direct and visual operations.

4. Visual and easy operations, easy to maintain.

5. Stainless steel tank – durable without leakage or rust.

Specification: Water MTC

Oil MTC

Operation temperature for water type MTC is 30-100°C whereas oil type MTC can reach 45-160°C.

Features:

1. PID temperature control – regulates error within 0.1°C, continuously and constantly, with high efficiency and energy saving.

2. Automatic exhaust & shut down cooling protection, thermostatic and circuit alarm, phase fault protection, pump protection, overheat protection, oil shortage protection.

3. LCD shows the actual and set temperatures – direct and visual operations.

4. Visual and easy operations, easy to maintain.

5. Stainless steel tank – durable without leakage or rust.

Specification: Water MTC

Oil MTC

Robotic System

Robots can extensively be applied to Injection Molding Machine.

Simple yet economical Swing-Arm and Single Axis Robot can be used to take out runners or products, while more advanced Three/Five Axis Servo Driven Robot can be applied for more complex requirement.

Special design robots are also available, such as Side-Entry In Mold Labeling Robot, 8-Axis Arm Robot, Painting Robot, etc.

Features:

1. Control system with friendly and easy operation interface

2. Rigid structure, stable construction, and low vibration design

3. High performance Servo motor

4. Maximum protection by multiple limit sensors

Simple yet economical Swing-Arm and Single Axis Robot can be used to take out runners or products, while more advanced Three/Five Axis Servo Driven Robot can be applied for more complex requirement.

Special design robots are also available, such as Side-Entry In Mold Labeling Robot, 8-Axis Arm Robot, Painting Robot, etc.

Features:

1. Control system with friendly and easy operation interface

2. Rigid structure, stable construction, and low vibration design

3. High performance Servo motor

4. Maximum protection by multiple limit sensors

Accessories & Spare-parts

Every purchase made with us, comes with full 1 year after sales service warranty.

Our spare-part division has a complete list of consumable parts and accessories.

Spare-parts are available to purchase for our existing clients, while accessories are available to all customers.

List of Accessories:

1. Hopper Magnet

2. Hot Air Recycle

3. Mold Clamp

4. Level Pad

5. Mold Rack

6. Material Tank

7. etc....

List of Spare-parts:

1. Cone & Mesh

2. Heater

3. Control Panel

4. Motor & Blower

5. Electrical Parts

6. Crusher Blade

7. V-Belt

8. etc...

Our spare-part division has a complete list of consumable parts and accessories.

Spare-parts are available to purchase for our existing clients, while accessories are available to all customers.

List of Accessories:

1. Hopper Magnet

2. Hot Air Recycle

3. Mold Clamp

4. Level Pad

5. Mold Rack

6. Material Tank

7. etc....

List of Spare-parts:

1. Cone & Mesh

2. Heater

3. Control Panel

4. Motor & Blower

5. Electrical Parts

6. Crusher Blade

7. V-Belt

8. etc...

Oil & Lubricants

To fulfill our client's need, we cooperate with Oil and Lubricants manufacturer. Our list of products are guaranteed to be genuine and COO certified. Fast moving Industrial Oil such as SHELL TELLUS, SHELL HYDRAULIC S1, SHELL CORENA, tube grease such as Lube FS-2 are always available in stock. While other specific items will be available upon your request.

Contact us

- PT. GARUDA INTI MAKMUR ABADI

- Komplek Bizpoint, Blok.J No.65, Cikupa - Tangerang - Banten